18/04/2008

World class

The main problem with constructing a blue laser was the lack of supply of single crystals of Gallium nitride (GaN). This problem, in fact, became an opportunity for us. At our Institute we could generate the high pressure and temperatures needed to make synthetic diamonds. Therefore, it was easier for us than others to make GaN. After over 10 years research, we succeeded in divising the technological process for making single crystals of the semiconductor, with crystalline equality by far exeeding that achieved in others laboratories around the world. This extremely important result formed the foundation for developing in Poland the technology for making blue lasers – saying prof. Sylwester Porowski, Institute of High Pressure Physics of the Polish Academy of Science.

Professor Sylwester Porowski: I wish our Institute to succeed in being the world fist to develop a viable technology for green semicondutor laser

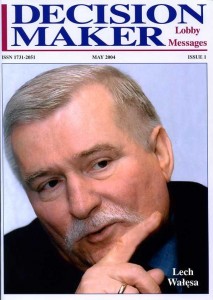

Prof. SYLWESTER POROEWSKI, PhD

Director of the Institute of High Pressure Physics

at the Polish Academy of Sciences

talks to Damian A. Zaczek

Professor Porowski, how did the idea to build a blue semiconductor laser originate?

In the public perception lasers are often associated with the straight beams of visible light used in the entertainment industry and light shows. However, semiconductor lasers are different, even though they are based on the same phenomenon first described by Albert Einstein. A semiconductor laser is a device which in an extremely efficient way converts electrical energy into light of very specific properties, namely coherent light. The first semiconductor laser was demonstrated over 40 years ago and was made from Gallium Arsenide (GaAs). It emitted infrared light. A few years later red light emitting lasers were also made. The colour of the laser light depends on the material from which such device is made. Very early on it was understood that the ideal base materials for making a blue laser are single crystals of Gallium Nitride (GaN). This semiconductor is ideally suited to generating blue light. It does not, however, occur naturally and its synthesis and crystallisation require extreme conditions which are even more demanding than those employed in making diamonds. Because of these problems, the Japanese decided to use sapphire crystals as a base on which they built the active part of their laser from Gallium Nitride. The first working blue semiconductor laser of this type was demonstrated by Shuji Nakamura in 1996.

How did the Polish initiative and program start?

As I mentioned earlier, the main problem with constructing a blue laser was the lack of supply of single crystals of Gallium Nitride (GaN). This problem, in fact, became an opportunity for us. At the Institute of High Pressure Physics of the Polish Academy of Sciences we could generate the high pressures and temperatures needed to make synthetic diamonds. Therefore, it was easier for us than for others to make Gallium Nitride. After over 10 years of research, we succeeded in devising the technological process for making single crystals of this semiconductor, with crystalline quality by far exceeding that achieved in other laboratories around the world. This extremely important result formed the foundation for developing in Poland the technology for making blue lasers. Effectively, the excellent quality of our GaN crystals presented us with an opportunity for a viable competition in certain areas with Japanese technology.

When did your team commence work in this area?

We started investigating the properties of Gallium Nitride in the early 80s, and ten years later we initiated work on crystal synthesis. The government-funded program targeting development of the blue lasers commenced in 2000. The first Polish laser was demonstrated in 2001.

What does your Polish patent cover?

It covers the technology of growth of single crystals of Gallium Nitride and their use for laser production. Of prime importance is our patented procedure for obtaining laser structures using molecular beam epitaxy (a thin-film deposition method), which frees us from having to use Japanese patents.

Who is financing the research and the production start-up?

We are an institute of the Polish Academy of Sciences and our key sources of funding are government programs. However, the blue laser program has been co-financed by a private investor, who jointly with our institute created a spin-off company called TopGaN.

What are the main areas of application for blue lasers?

It is a common knowledge that red light lasers are used in, for example, CD

and DVD recorders or in medicine. One of the key advantages of blue lasers is that they generate light of a very short wavelength. This, in the case of recording on a disk, may be compared to writing with a much sharper pencil. In other words, it enables smaller marks to be made, which translates into packing more information without increasing the surface area of the recording medium.

On the other hand, having at our disposal red, blue and green lasers, we will be able to generate inexpensively ultra high resolution images with very high color saturation. This is directly related to the working principles of human eye.

The third area of immediate applications takes advantage of the very high energy carried in the quantum of blue or ultraviolet light. Such high energy quanta can stimulate fluorescence in a wide range of substances, which facilitates their detection at extremely low levels. The first laser instruments to use this phenomenon are already being deployed in the fields of medicine, defense and environmental protection.

Are there any immediate mass-market applications?

The Japanese have produced the first DVD recorders using the blue-ray system, which enables a five-fold increase in recording density over traditional media. One disk can hold 25GB, or even 50GB. These products are just starting to enter the market.

What type of lasers does TopGaN make?

Two types of lasers are being made. The first are high power pulsed lasers. These are used mainly in spectroscopy. Such lasers emit light in 50 nanosecond-long pulses, with one second delivering between 10,000 and 100,000 pulses of 1000 mW peak power. The second type of lasers is used to generate light continuously. Their production is only starting. At the moment we are selling engineering trial versions that have an optical power output of up to 200 mW. The scope of potential applications for these lasers is very wide. At present, these lasers are being used for development of new display technologies, in medical diagnostics and therapy and in environmental protection.

What is the current production level?

Presently it is still on the laboratory scale: several dozen units a year. However, we are starting construction of a production facility, with a target throughput of tens of thousands units a year. At the same time we are engaged in negotiations with several companies which have already expressed interest in buying our lasers.

What is your team working on currently?

The work on setting up the production of blue lasers is TopGaN’s responsibility. The main effort at the institute is focused on developing ultraviolet laser technology. Such lasers emit light of even shorter wavelength, with higher energy quanta, which further expands their applicability in biology and medicine. We are also working on developing the world’s first Gallium Nitride based green laser. It is an incredibly important, but very difficult target. However, our growth technology, which uses much lower temperatures for the deposition of the critical laser regions, gives us significant advantage over the technologies used by the Japanese competitors

Why is the third colour, green, still missing from the line-up?

A green semiconductor laser is even more difficult to make than a blue one. In short, this is due to requirements put on the composition of the critical active layers in such a device (it requires significantly increased Indium content, which leads to degradation of the crystalline quality for the entire structure). The very high quality of our starting GaN crystal material should help considerably in avoiding such catastrophic degradation. This is exactly what we are counting on.

Professor Porowski, switching to the broader context, what is your assessment of the state of science in Poland?

I believe that there is a whole range of world-class science being done in Poland. In some fields, such as biotechnology, spintronics, blue optoelectronics or IT we are in the tight world leadership. However, it was the government’s policy up until now to distribute funds to all the fields equally. There was no mechanism in place that would have enabled us to favor directions with potentially significant economical impact, the directions in which we could not only enter the global competition, but also stand a significant chance of becoming the world leader. The current proposals for reorganizing Polish science are heading in the right direction. The new system of funding will favour large projects having both fundamental and applied research components, leading towards commencing specific production. Such projects may require the formation of interdisciplinary research teams.

Is Polish industry likely to be co-funding such programs?

If the proposed projects are realistic and aligned well with the market then I am quite optimistic. I believe that we will slowly succeed in working out the methods for this type of cooperation. However, I anticipate that this will not be an easy process and that in its initial phases government support will have to be significantly stronger than in the more developed countries.

Are foreign companies able to co-finance these programs?

Yes, of course. For example the recently set up European Technology Platforms may help very significantly in this.

What do you wish for as a scientist?

I wish that in the areas where Polish science is really strong, well-financed research programs will be initiated and will include, apart from ambitious theoretical objectives, important practical goals as well. At a more personal level, I wish our institute to succeed in being the world fist to develop a viable technology for the green semiconductor laser.

Professor Porowski, thank you very much for this very interesting and illuminating conversation.

CHRISTMAS

Exotic and traditional

In certain regions of Poland, where Catholics and Orthodox live side by side, there is an old debate going on regarding the “authenticity” of Christmas, in others words, the date when Jesus’ birth should be celebrated. więcej...